Mechanical Stability Of Cold Seal FP2200 |

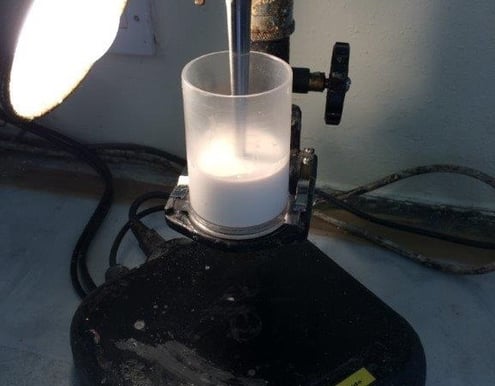

Mechanical Stability Test – Klaxon Stirrer |

Bond Strength & Adhesion To OPP |

FPP Crimp Sealing Unit |

Performance Summary – FP2200 |

- Spindle revolves at 14000 RPM , creating a vortex with extremely high mechanical shear on the rubber latex particles.

- The end result of and unstable cold seal – the rubber particles have coagulated due to the high mechanical shear.

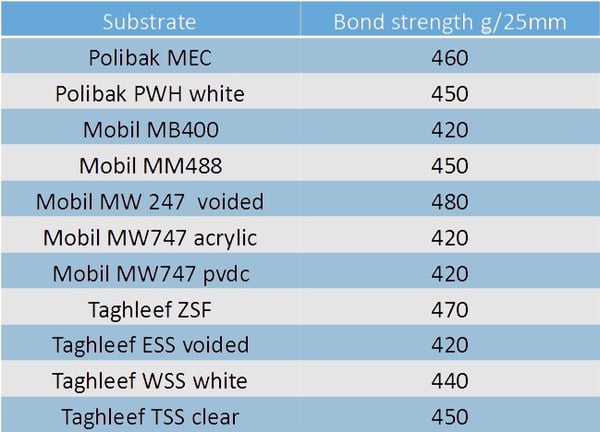

Bond Strength & Adhesion To OPP

Bond strength (cohesion) and adhesion to the substrate are closely linked, this balance between natural rubber latex and the other polymers in the formulation is key to achieving the best performance from a cold seal.

The rubber latex provides the cohesion and a blend of low odour polymers provide the adhesion to the untreated OPP.

FPP Crimp Sealing Unit

|

|

| 25mm sample is sealed at 30psi for a dwell time of 1 second. | The sealed sample is held at 90 degree angle and pulled apart at 200mm/minute. |

Back to top

Performance Summary – FP2200

- Vastly improved mechanical stability – delivering better doctor blade wipe.

- Very low ammonia level to reduce vapour discomfort for press operators.

- Strong seal strengths on untreated OPP films at low coating weights.

- Good rub resistance.

- Satisfactory release in the reel from polyamide release lacquer.

The table demonstrates expected values when cold seal FP2200 is thoroughly dried at a coating weight of 3.0 gsm dry, and sealed with a crimp jaw.

Back to top